Sustainable Water Treatment Agreements

A Sustainable Water Treatment agreement includes products, monthly testing, and maintenance of water treatment equipment. Optional services include Legionella testing and cooling tower cleaning. Electronic reports are emailed and can be downloaded anytime at www.mySWTreports.com. Agreements are set up for 1–3-year terms.

Control and Feed Equipment and Installation

Automated control and feed equipment is recommended to keep systems running efficiently. SWT can provide, install, and set up automated feed equipment for heating and cooling water systems.

New Construction Projects

SWT offers all chemicals, equipment, installation, and setup for new building projects. Information is gathered from specs and drawings for SWT to provide the water treatment requirements for your new building project.

Heat Exchanger Cleaning

Fouled heat exchangers are typically due to scale or microbiological contamination. This will increase energy costs and cause costly maintenance, repairs, and downtime for process applications. SWT provides heat exchanger cleaning services to get your systems back online and running more efficiently.

Closed Loop Cleaning and Filtration

Neglected closed loop systems may require cleaning before proper treatment can be effective. SWT can provide online and offline closed loop cleaning. We also recommend installing bypass filter feeders for all closed loop systems. This reduces iron sediment and debris that can foul systems and damage pump seals. SWT can provide and install closed loop filter feeders.

Glycol Addition

Some closed loop systems may require glycol to prevent freezing and bursting of pipe and equipment. SWT can size your system and provide an adequate amount of glycol to prevent freezing.

Acid Cleaning for Chillers and Boilers

Chillers and boilers may be fouled by scale deposits due to lack of treatment, blowdown valves that get closed, pumps that do not work properly, or other chemical and mechanical issues. Scaled heat exchange surfaces will increase energy costs and can only be cleaned by circulating properly designed cleaners. SWT can provide products, equipment, and service to clean your systems safely. Clean heat exchange surfaces will maximize system efficiency.

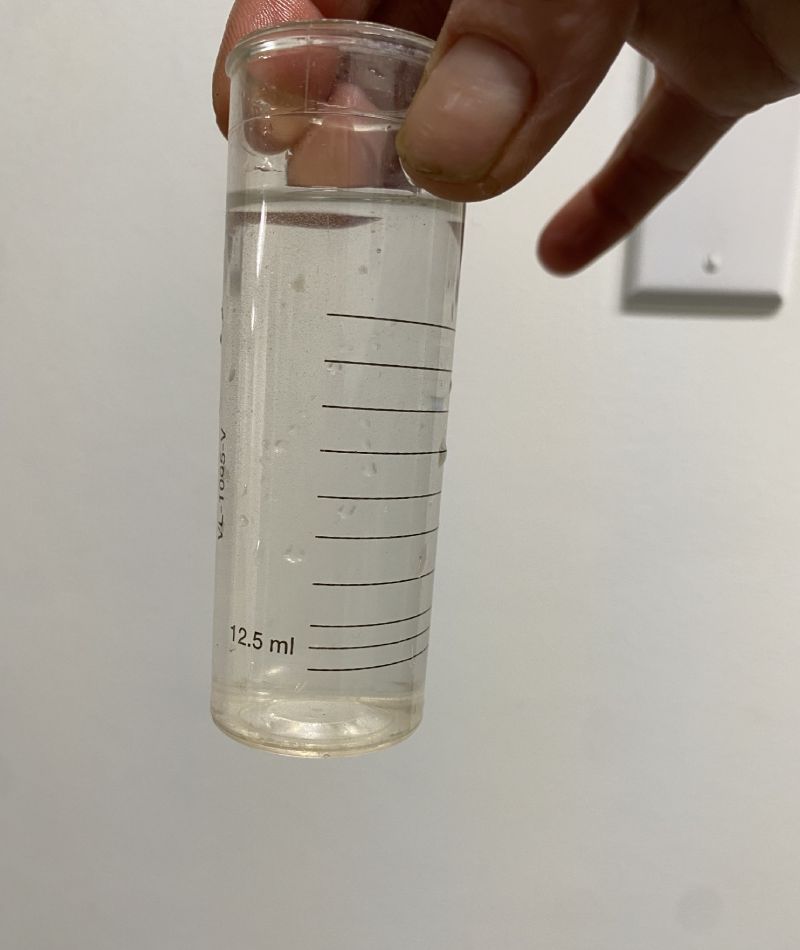

Lab Testing

Sometimes we need more details! To properly clean or prevent a fouling issue, SWT uses an accredited lab to analyze deposits, water, and corrosion coupons.

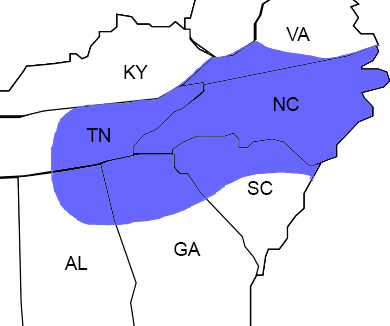

Legionella Testing and Abatement

Sustainable Water Treatment will share knowledge and offer advice on practices used to minimize the risk of Legionella in cooling tower systems. Minimizing risks include eliminating dead legs, preventing stagnant lines and basins, annual tower cleaning, alternating biocide program, include at least one oxidizing biocide, cooling tower filtration and chemical feed equipment automation. Reducing the risk of Legionella is dependent upon a facility team which can include managers, maintenance staff, mechanical provider, water treater, etc.